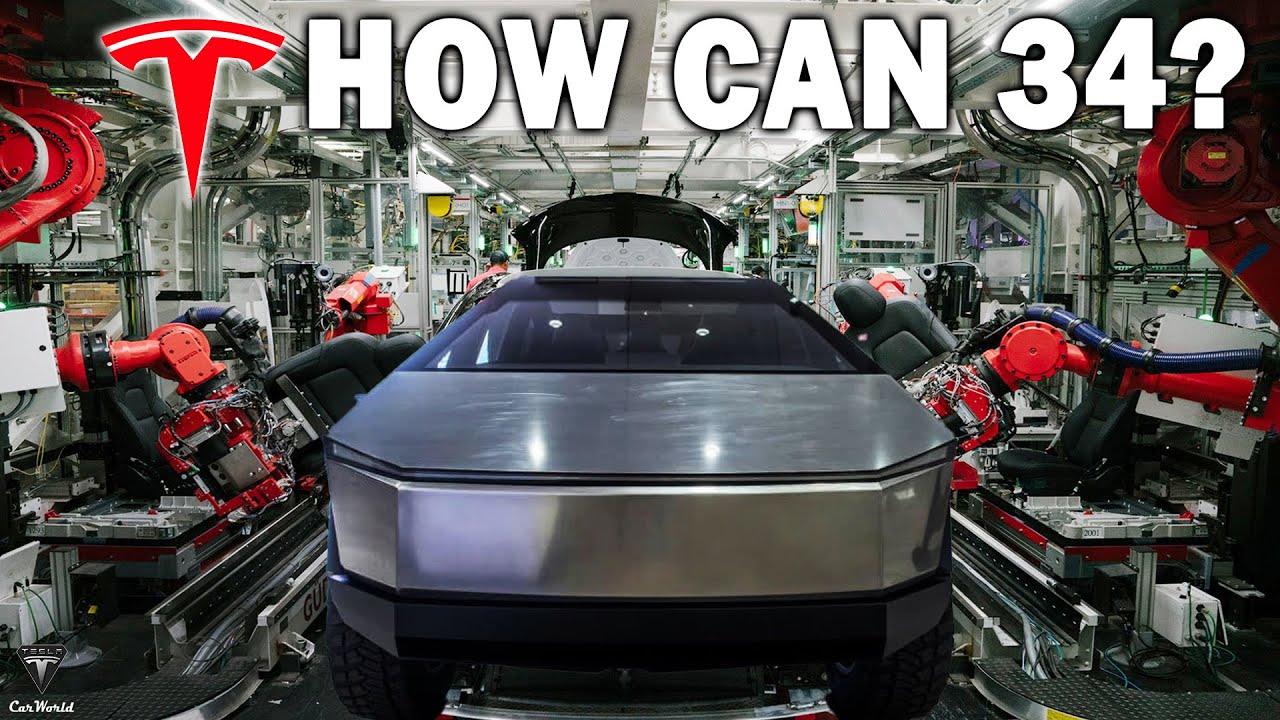

How Tesla Builds a Car Every 34 Seconds: The Secret Behind Gigafactory Shanghai’s Record-Breaking Speed

Imagine a factory where a fully assembled Tesla Model 3 or Model Y rolls off the production line every 34 seconds.

Sounds unbelievable? Yet, this is the reality at Tesla’s Gigafactory Shanghai, a marvel of modern manufacturing that’s reshaping the automotive industry.

How does Tesla achieve such staggering speed without compromising quality? What innovations power this production miracle? Let’s dive into the fascinating world of Tesla’s lightning-fast car manufacturing and discover the secrets behind this game-changing process.

In 2023, Tesla shattered records by producing over 1.35 million vehicles within just nine months, with nearly 700,000 of those being Model 3 and Model Y units sold in China alone.

Gigafactory Shanghai hit a monumental milestone by rolling out its two-millionth vehicle, doubling its output in a mere 13 months after hitting the first million.

This rapid acceleration in production underlines Tesla’s dominance in the electric vehicle market and its ambition to make EVs mainstream worldwide.

A core enabler of this unprecedented speed is Tesla’s revolutionary use of Giga casting technology.

Unlike traditional car manufacturing, which involves assembling dozens of individual components, Tesla casts large, complex parts—such as the entire rear underbody—in a single piece.

This innovation dramatically reduces assembly complexity, lowers production costs by up to 40%, and cuts vehicle weight by over 10%, translating into better performance and extended driving range.

Tesla’s approach to prototyping and tooling is equally groundbreaking.

The company employs industrial sand 3D printers that build molds layer by layer, allowing for rapid iteration and precise casting.

This method not only accelerates production but also ensures structural integrity by eliminating joints and welds common in conventional manufacturing.

Battery supply is another critical factor.

Tesla benefits from its proximity to CATL, the world’s largest battery manufacturer, located in China.

CATL’s advanced production lines churn out one lithium-ion battery cell per second with 95% automation, assembling full battery packs in just two and a half minutes.

This seamless supply chain integration minimizes downtime and supports Tesla’s relentless production pace.

Despite the astonishing figure of 34 seconds per vehicle, it’s important to clarify that this number represents the average output rate—not the total time to build a single car from start to finish.

The entire assembly process takes over two and a half hours, involving a coordinated ballet of 445 robots and thousands of skilled workers operating around the clock.

The factory’s efficiency lies in this continuous, overlapping workflow, ensuring a steady stream of finished vehicles without interruption.

Tesla’s mastery of automation and human-machine synergy is reminiscent of historic manufacturing milestones, like Ford’s assembly line, but elevated to a new level of precision and speed.

This synergy is a cornerstone of Tesla’s ability to produce high-quality electric vehicles at scale while driving down costs.

The ripple effects of Tesla’s manufacturing breakthroughs are already influencing the broader automotive industry.

Toyota, for instance, has drawn inspiration from Tesla’s Giga casting techniques to simplify its own production lines, reducing parts count and boosting profitability.

Such cross-industry adoption underscores Tesla’s role as a pioneer in modern vehicle manufacturing.

Tesla’s success at Gigafactory Shanghai also fosters a thriving local supply chain ecosystem.

The factory collaborates with over 360 tier-one suppliers, many of whom now compete internationally.

This symbiotic relationship fuels innovation in China’s new energy vehicle sector, benefiting the entire industry from concept development to final assembly.

Looking ahead, Tesla’s expansion plans are ambitious.

Discussions are underway to establish new gigafactories in Turkey, Saudi Arabia, Mexico, and India—each strategically positioned to tap into regional resources, labor markets, and emerging EV demand.

The planned Mexico Gigafactory, for example, is expected to produce Tesla’s next-generation platform, including the highly anticipated affordable Model 2 priced around $25,000.

India represents a particularly promising frontier.

With vast lithium reserves, growing battery manufacturing capacity, and government initiatives targeting substantial EV adoption by 2030, India could become a key player in Tesla’s global manufacturing strategy.

Tesla’s ongoing engagement with Indian officials and investments hint at a future plant that could replicate Shanghai’s production miracle on Indian soil.

Tesla’s relentless pursuit of efficiency extends beyond manufacturing speed.

The company continuously optimizes its supply chain, production processes, and product design to halve costs and improve vehicle range.

These efforts align with CEO Elon Musk’s vision of making electric vehicles accessible to the masses and accelerating the world’s transition to sustainable energy.

In summary, Tesla’s ability to produce a car every 34 seconds at Gigafactory Shanghai is a testament to relentless innovation, cutting-edge technology, and masterful operational execution.

From giga casting and automated robotics to integrated battery supply and global expansion plans, Tesla is rewriting the rules of automotive manufacturing.

As Tesla scales these breakthroughs globally, the question is no longer if electric vehicles will dominate the future, but how quickly Tesla’s manufacturing prowess will reshape the entire industry.

For EV enthusiasts and industry watchers alike, the factory floor at Gigafactory Shanghai offers a thrilling glimpse into the future of fast, efficient, and sustainable car production.

News

DNA Shocker: Could This Polish Woman Really Be Madeleine McCann? – HTT

DNA Shocker: Could This Polish Woman Really Be Madeleine McCann? In a case that has captivated the world for nearly…

Valerie Bertinelli’s ‘Getting Naked’ Memoir: The Shocking Truth Behind Her Deepest Struggles – HTT

Valerie Bertinelli’s ‘Getting Naked’ Memoir: The Shocking Truth Behind Her Deepest Struggles When Valerie Bertinelli appeared on The Drew Barrymore…

From Friends to Food Icons: Bobby and Brooke’s Big Announcement Shocks Fans – HTT

From Friends to Food Icons: Bobby and Brooke’s Big Announcement Shocks Fans Imagine the dazzling lights of New York City…

32 Years Later: The Jaw-Dropping Reason Trump Honored Charlie Kirk – HTT

32 Years Later: The Jaw-Dropping Reason Trump Honored Charlie Kirk In a deeply moving gesture, Erika Kirk, the widow of…

Trump’s Unexpected Gesture: Erika Kirk’s Emotional Reaction to Her Late Husband’s Legacy – HTT

Trump’s Unexpected Gesture: Erika Kirk’s Emotional Reaction to Her Late Husband’s Legacy In a deeply moving gesture, Erika Kirk, the…

NFL SHOCKED as Dillon Gabriel Faces Suspension Over Shedeur Sanders Insult! – HTT

NFL SHOCKED as Dillon Gabriel Faces Suspension Over Shedeur Sanders Insult! In the world of college football, rivalries are often…

End of content

No more pages to load