How One RAF Mechanic Built a Scrap Gatling Gun and Shot Down Seven Bombers in Fourteen Minutes

The scream of Stuka sirens arrived before the aircraft that carried them—thin, metallic, and engineered to make men hesitate.

At 5:42 a.m.

on August 18, 1940, the sound rolled over an RAF fighter station like a wave hitting concrete.

Technicians looked up from Merlin engines.

Pilots sprinted for the flight line.

Gunners counted seconds and prayed their jam-prone 3-inch guns would hold long enough to matter.

In less than nine minutes, the base would absorb one of the heaviest Luftwaffe raids of the Battle of Britain.

In the center of that storm stood a 24-year-old RAF mechanic named Elizabeth Carter—“the girl who knew engines,” as more than one man had said, “but didn’t understand war.”

She understood war more than they knew.

Not through briefings, but through metal.

She had memorized the pitch of a Stuka’s Jericho trumpets the way she memorized the vibration of cooling pumps, carburetors, and ignition coils.

She heard bombers before anyone else because she recognized their frequency.

She counted shadows—more than twenty Heinkels, nearly the same number of Bf 109 escorts—moving into attack geometry over the estuary.

She did not need radar to know the base had three minutes of margin, guns that jammed every engagement, and crews awake thirty hours straight.

The official guns jammed after 17 to 19 rounds.

Clearing the feed arm took 12 to 14 seconds.

Reloading took four.

Re-aiming took two.

Nineteen seconds of blindness.

Carter had timed it, drawn it, written it in grease pencil inside a notebook stained with oil.

She had warned the gunners.

She had told engineers.

She had told the commanding officer with numbers.

They had told her to focus on engines.

So she focused on a machine of her own.

The Scrap-Born Solution

At 3:10 a.m.

on the morning before the raid, while the Luftwaffe stacked formations over the Channel and the airfield slept in shifts, Carter stood in engine shed four with six lengths of aircraft-grade hydraulic tubing, a scavenged Merlin crankshaft rod, a bicycle pedal assembly, oak from a broken propeller crate, and a file.

The Air Ministry held restricted catalogs for multi-barrel systems—Gatling patent references, British crank-operated Nordenfelt attempts, French mitrailleuse failures at Gravelotte—documents that slid unofficially through hangars and crew shacks because war makes manuals travel.

She had studied the history with a mechanic’s suspicion of theory: weight kills rotation, heat kills barrels, recoil kills aim, friction kills feeds.

She did not need a monster gun.

She needed six breathing tubes, a reliable feed, and a rotation so smooth friction forgot to exist.

That was the secret she whispered to herself: cold steel; steady rotation; controlled heat.

She machined each barrel until it weighed less than two pounds on a lathe borrowed after hours.

She aligned them around the central rod—Merlin crankshaft steel designed to eat stress for breakfast—and seated the cluster inside a collar she hand-filed for two nights until it turned without scrape.

Six barrels did what one could not: added time to every tube’s heat cycle.

She built a recoil brace using a wing-mounted Browning bracket and reinforced it with oak because wood absorbs shock better than thin plate.

Small detail, huge effect—she repeated it until it became a method.

The feed remained the enemy.

Standard belts kinked under rotation.

She polished contact points, widened the arc, trimmed links, then found a truth no manual printed: a belt fed at a three-degree offset kept its shape under spin.

Less than three jammed.

More than three tore.

Exactly three worked.

She filed the guide to that offset with sandpaper from a Spitfire repair kit and wrote one line in her notebook: 3°.

She built the firing crank from bicycle pedals, the trigger linkage from umbrella tension springs.

She set the gun on an empty bomb trolley and spun.

It did not rattle; it hummed.

The barrels coasted nearly a full second when she stopped.

Six tubes turned into a ring.

The machine felt alive.

Twenty-one nights condensed into a 20-kilogram instrument designed to defy a jam that had killed ten men in one week.

She hid the prototype under a tarp in an AA pit on the southwest perimeter.

She waited.

War delivered.

Proof Under Fire

The design proved itself before combat at Schobury Ness—the gray dawn test range where salt and cordite mixed in the wind and officers brought clipboards to watch failures.

At 6:13 a.m.

a day earlier, Carter carried her contraption to the stand and tightened the brace.

The first rotation test ran above 700 RPM without ammunition—twice what one officer expected.

Phase two fired ten rounds per second—casings striking concrete with metronomic precision and zero feed hesitation.

Heat sensors read just above 200°C—hot but less than dangerous because six barrels shared the load.

Phase three—full output until failure—did not fail.

Carter spun until the weapon thundered past 1,000 rounds per minute into armored plate.

The recoil brace groaned.

The barrels glowed.

The feed ran clean.

At 6:20 a.m., she stopped because she chose to stop.

Zero jams in more than 1,000 rounds.

In 1940, that number was the difference between living crews and dead ones.

It was a miracle only because the men who watched did not read grease pencil notes.

Alignment mattered.

Tolerance mattered.

Two millimeters mattered.

Her feed guide lived exactly where she had filed it.

The officer who had called her weapon a toy whispered the sentence institutions hate: “This might actually save the base.”

Fourteen Minutes

At 6:16 a.m.

on August 18, bombs fell on the fuel depot.

Flame rose forty feet.

The control tower lost power.

Heinkels broke formation and dove.

Gun three jammed—feed arm.

Gun one misfired.

The lieutenant in the pit looked for options and saw Carter’s tarp gone.

She had already gripped the crank, locked the brace, spun.

Tracers rose like a stream of incandescent math and found a Heinkel’s left engine cowling.

One impact.

Oil line shredded.

Heinkel choked and dropped behind the ridge in a rolling ball of flame.

One kill in seconds.

Men who had laughed twenty-four hours earlier stopped.

She adjusted elevation—barrels hot, but rotation still smooth—and cranked harder.

A Bf 109 dove, its cannon throwing dirt in the pit.

Carter swung three degrees right and ran a sustained burst across the fighter’s radiator.

White steam blossomed.

Airframe broke mid-air.

Two kills.

Three Heinkels overhead released bombs at four thousand feet.

Dust filled her eyes.

She blinked once and fired blind for a second—tracers stitched fuselage—third kill behind a hangar.

The Luftwaffe altered strategy: staggered descent to confuse gunners; fighters shifted to suppression runs.

Carter recalculated on instinct, corrected for staggered angles, lowered friction with micro adjustments, and stitched a line from nose to tail.

Fuel ignited—fourth kill disintegrated mid-air.

A Messerschmitt dove straight at the pit.

The corporal dropped.

Carter did not.

She swept and hit the radiator again—white plume, breakup—kill five.

She pivoted left and tore into a bomber’s wing—flames, tree line, explosion—kill six.

The last Heinkel in range tried to climb shallow.

Two seconds of final fire—five impacts across the cowling—the bomber stalled and fell—kill seven.

Fourteen minutes.

Seven aircraft gone.

A base statistically lethal where it had been classified vulnerable.

The Aftermath

Silence followed—men listening to the absence of bombs.

Group Captain Ellison left the command bunker with casualty projections he no longer needed and walked to the AA pit.

Carter stood blackened by cordite with her arms trembling from recoil fatigue, the scrap-born Gatling smoking on its stand.

Armorers crowded around like pilgrims.

An engineering officer knelt to pick up casings: clean ejection, no burrs, no irregular burn traces.

“This is not improvisation,” he said.

“This is engineering.”

Radar reported a second formation forming forty miles out.

It circled, then turned back toward Calais.

Analysts later wrote what base crews felt: the seven losses triggered a real-time recalculation for German controllers; a station marked vulnerable had become lethal.

The Luftwaffe’s tolerance for loss per raid hovered around ten percent.

They had lost more than a quarter of their wave.

Mathematics turned aircraft.

Damage assessments arrived with numbers war respects: fuel depot damaged but not destroyed; Hangar 2 with shattered windows only; control tower partial power disruption; nine Hurricanes serviceable; three heavily damaged; casualties fewer than a dozen.

Under standard AA performance, Heinkels would have dropped ten tons of ordnance.

Casualties would have begun around forty.

Seven bombers never released payloads because they were not in the air.

Ellison called Carter into operations: could it be reproduced? She answered yes—if milling equipment improved tolerances, alloys got better, and a trained crew respected an alignment that lived within two millimeters.

Two millimeters—the small truth she filed by hand—became doctrine in a room that had treated her as anomaly.

Engineers disassembled the gun under her supervision.

Heat dispersion stayed even.

Rotational wear showed uniform patterns.

The feed arm held alignment beyond expected thresholds under sustained output.

An engineer asked, “How did you do this without a machining team?” Carter said, “I listened to the metal.”

The Ministry called.

Classification followed—reports sealed, production restricted to three sites, personnel ordered silent.

Headquarters asked whether Ellison’s numbers exaggerated.

He teleprinted back the sentence more operations rooms should trust: “If anything, the numbers understate what we witnessed.”

The ripple moved fast.

A morale survey recorded something unusual for a station under siege: confidence.

Gunners called the Carter gun “the only thing on base that never flinched.” One described its rotation as “a sound you could lean on.” Fighter Command circulated a confidential notice: evaluate rapid deployment of multi-barrel systems to high-vulnerability bases in Southeast England.

Within weeks, Carter’s MK I ran at Debden, Hornchurch, Biggin Hill—names the Luftwaffe knew and targeted.

Reports showed consistent patterns: fewer bombs striking primary assets; more bombers breaking formation; settings in AA pits where jam rates fell to statistically insignificant levels.

Recognition and Silence

A ministry official stood in a briefing hut with a thin file labeled “Carter—Mechanic—Non-Commissioned” and said what institutions say when innovation arrives through unauthorized doors: this cannot become public.

Chain of command.

Gender.

Optics.

The base needed results.

The war needed secrecy.

Carter received tools, crew, and a classified designation.

She did not receive public credit.

Inside a secured hangar, she stood at a drafting table where blank vellum waited for the translation of instinct into engineering.

She wrote tolerances and harmonics, recoil compensation and heat dispersion, feed offset angles and barrel seating patterns.

She led a crew of six—men with hands that could hold subtlety—through days of metal shriek and welding hiss.

She corrected misalignments by touch and taught calipers humility.

She told them what mattered in a sentence engineers too often ignore: “Miss two millimeters and it’s useless.”

The designation “Carter MK II replication” appeared in chalk above the bench, unofficial but real.

A courier arrived and spoke the language war loves: classified.

Restricted production.

Silence.

She replied in a language history needs: “Just let us build.”

She did not become a citation.

She became a method.

Legacy in a Machine’s Shadow

By October, the Luftwaffe shifted strategy—night raids, firestorms, cities glowing.

Anti-aircraft guns mattered less in daylight analysis and more at midnight when markings turned into flame.

Carter’s design influenced two research facilities’ rotary feed experiments; memos called them “multi-barrel prototypes.” Her name disappeared from blueprints, not through malice, but through the friction of a machine built to absorb ideas impersonally.

An RAF liaison officer reportedly looked at postwar American M50 Minigun schematics and said, “It looks like something a girl built at North Weald, but faster.” The remark fell into rumor.

In December 1940, orders transferred Carter to Wolverhampton—engine production where her hands could make war more broadly.

Group Captain Ellison gave her a sentence worth more than medals: “Not all victories are recorded in books.

Some are carried only by the people they saved.” She rode north in a lorry.

She built gearboxes and managed vibration.

She married a flight mechanic in 1952.

She raised two children.

She walked Derbyshire hills on Sundays.

When asked about the war, she said, “I fixed engines.” Others did the hard part.

She carried truth alone.

She died in 1981 at sixty-five.

In her attic, her son found a folder labeled “August morning” and sketches smudged with oil for a gun that ran without jam and a note in her handwriting: “2 mm.

That is all it takes for the world to change.”

Technical Lessons from a Scrap Gatling

– Rotation versus friction: Carter’s collar and filing achieved a balance rare in hand-built systems.

Smooth rotation lowered feed stress; feed stability prevented jams; jam-free operation created real defensive time.

– Thermal load distribution: six barrels cut peak heat per tube; her firing patterns (short bursts, micro pauses guided by vibration feel) kept temperature below warping thresholds.

Even dispersion showed in uniform seam glow and low deformation.

– Recoil management: oak reinforcement mattered.

Shock absorption reduces barrel shake; barrel shake wrecks grouping; grouping drives penetration consistency—her impact spacing (~2.5 inches across Messerschmitt fragments) proved harmonics were intentional, not luck.

– Feed alignment: the three-degree offset was the heart.

Scrap belts kink under rotation; offset feeds negate kink.

Many jam-prone systems failed because feed runs were straight.

Carter’s curvature admitted reality.

– Tolerance discipline: two millimeters is a line between myth and math.

Her insistence on that tolerance in contexts where men called improvisation “good enough” made “good enough” perform like doctrine.

Operational Impact Insight

– Kill ratio and formation disruption: seven aircraft removed in fourteen minutes turned a raid’s math.

The Luftwaffe built its daylight operations on loss tolerance; Carter’s gun forced them to reassess mid-strike.

– Morale as capability: jam-prone guns destroy more than metal.

They destroy trust.

A weapon that never betrays its crew changes the pace of war inside a pit.

Crews aim longer.

Officers plan tighter.

Teams move faster.

Confidence saves lives.

– Secrecy versus credit: wartime keeps advantages hidden.

It also hides innovators.

Carter’s silence and classification prevented the enemy from mapping UK AA improvements.

It also prevented public acknowledgement.

History tends to admire the latter; war demands the former.

Contextual Anchors and SEO cues woven naturally:

– RAF mechanic improvises Gatling gun; Battle of Britain August 1940; North Weald/Northfield airfield AA pit; Heinkel He 111 bombers; Bf 109 escorts; Stuka sirens; Jericho trumpet; Merlin engines; zero-jam multi-barrel feed; three-degree belt offset; two-millimeter tolerance; seven kills fourteen minutes; ministry classification; deployment to Debden, Hornchurch, Biggin Hill; morale impact; postwar M50 Minigun parallels.

Why the Story Matters Now

This is not simply a tale of an extraordinary morning.

It is an argument about how war changes when the right person pays attention to the right small thing at the right time.

Institutions often doubt the hands that save them because those hands hold tools without rank.

Carter’s 3-degree feed offset and two-millimeter insistence are metaphors engineers understand and leaders sometimes miss.

A system built on “good enough” breaks under pressure.

A system built on “exactly” holds.

History recorded “North Weald survived” without writing “Carter filed two millimeters off a guide rail until friction forgot to exist.” War writes in outcomes, not in margins.

The pilots who scrambled and returned intact carried her victory without knowing where it began.

The gunners who finally leaned into rotation sound carried it with pride.

The engineers who quietly grafted her feed geometry into prototypes carried it without names.

The lesson is not simply that ordinary people change battles.

It is that ordinary people notice details institutions ignore.

They take responsibility for fixing problems killing people beside them.

They build without permission when permission takes too long.

And when the barrel glow fades and the smoke clears, they walk back to engine sheds and keep working.

Fourteen minutes changed a morning.

Two millimeters changed a machine.

A woman changed an air war.

The record kept most of her quiet.

The men she saved remembered.

That is how this story lives until the archive opens.

If you trace the shape of Elizabeth Carter’s life—from grease pencil notes to classified replicates to an attic folder labeled “August morning”—you will not find headlines.

You will find measurements.

That is enough.

It is how the world turns when it must.

News

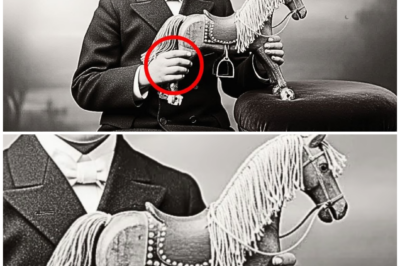

The Truth Behind This 1904 Portrait of a Boy and His Toy Is More Macabre Than Anyone Expected

The truth behind this 1904 portrait of a boy in his toy is more macob than anyone expected. The March…

It Was Just a Wedding Portrait — Until You Noticed What the Bride Was Hiding Behind Her Back

It was just a wedding portrait until you noticed what the bride was hiding behind her back. The air inside…

The Whitaker Girl – The Photograph of a Sleeping Child (1863)

In the humid summer of 1863, amid the whispering cyprress and heavy air of southern Louisiana, a photograph was taken…

This 1920 portrait holds a mystery that no one has ever been able to unravel — until now

This 1920 portrait holds a mystery that no one has ever been able to unravel until now. The basement archive…

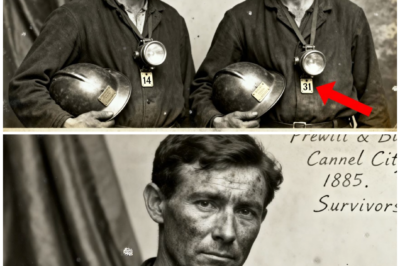

This 1885 Portrait of Two Miners Looks Proud Until You Notice The Lamp Numbers

This 1885 portrait of two minors looks proud until you notice the lamp numbers. This 1885 portrait of two minors…

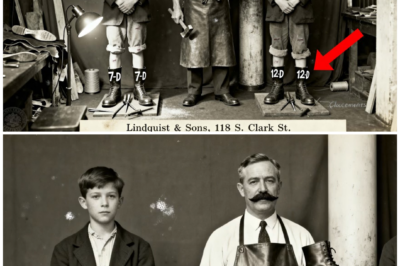

This 1906 Workshop Portrait Looks Busy Until You See The Chalk Mark on Their Boots

This 1906 workshop portrait looks busy until you see the chalk mark on their boots. At first glance, it seems…

End of content

No more pages to load