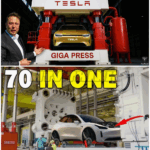

Tesla’s Revolutionary 50,000 Ton Giga Press: A Game Changer in Auto Manufacturing

In a groundbreaking development, Tesla has unveiled its latest innovation: a colossal 50,000 ton Giga Press machine capable of producing a new car every five seconds.

This monumental leap in manufacturing technology is set to redefine the automotive industry, as Tesla continues to push the boundaries of what is possible in electric vehicle production.

Elon Musk, the visionary behind Tesla, has likened this massive machine to a giant toy factory, emphasizing its potential to streamline production like never before.

The Giga Press allows Tesla to cast five vehicles simultaneously, a feat that has never been achieved in automotive manufacturing.

To understand the significance of this new machine, we need to look at the evolution of Tesla’s casting technology.

Tesla started with a 6,000 ton Giga Press to produce the rear underbody of the Model Y, which simplified the assembly line by replacing over 70 individual parts with a single solid aluminum piece.

Next came the 9,000 ton Giga Press, designed specifically for the Cybertruck’s body, showcasing Tesla’s commitment to innovation.

Now, the introduction of the 50,000 ton Giga Press marks a new era in production capabilities.

This machine is not just larger; it delivers around 8.3 times more pressing force than the 6,000 ton model and 5.5 times more than the 9,000 ton press.

Its sheer size and power will allow Tesla to produce vehicles faster and more efficiently than ever before.

The Giga Press operates on a high-pressure die casting principle, where molten aluminum is injected into molds shaped like the vehicle components.

This process begins with heating aluminum alloy in a furnace, followed by pouring it into precisely designed molds.

The Giga Press applies extreme pressure to ensure that the molten aluminum fills every detail of the mold perfectly, resulting in high-quality parts that are both lightweight and structurally sound.

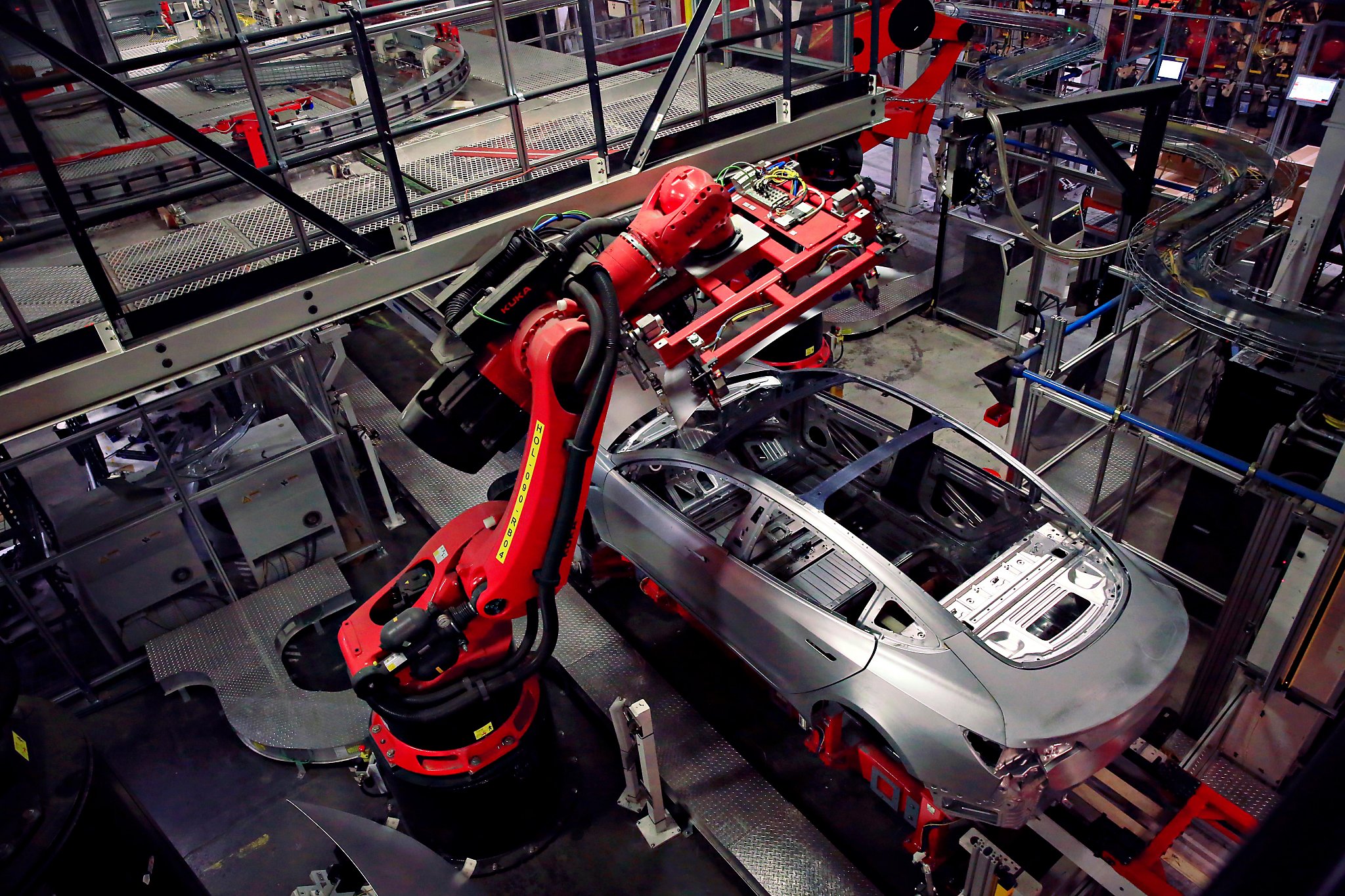

Once the aluminum cools and solidifies, a robot extracts the part, trims any excess material, and sends it through a quality inspection process.

This entire operation is automated, allowing for a seamless production flow that minimizes human error and maximizes efficiency.

With the new 50,000 ton Giga Press, Tesla aims to revolutionize its production line.

Musk has stated that the new line will be so fast that human workers won’t be able to keep up.

Each cycle of pouring the metal, cooling the mold, and separating the part from it takes only about five seconds.

This means that the frame of a car can be completed in the blink of an eye.

The scale of the 50,000 ton Giga Press is staggering.

It is estimated to be around 20 meters long, 12 to 15 meters tall, and 10 to 12 meters wide, weighing over 3,000 tons.

Tesla may need to construct a dedicated facility to house this machine, complete with a reinforced concrete foundation to support its immense weight.

The operational process of the Giga Press involves a two-furnace system for processing aluminum alloys.

One furnace melts new aluminum ingots and leftover aluminum from previous castings, while the other keeps the molten metal at a consistent temperature.

This ensures that the aluminum remains in optimal condition for casting, preventing oxidation and other impurities.

Before each casting cycle begins, the Giga Press lubricates the mold surface to facilitate the release of the finished part.

A robot sprays a thin layer of soybean oil onto the mold, creating a non-stick surface that aids in the extraction process.

Once the mold is prepared, the molten aluminum is injected at high speed, filling the cavity and solidifying into the desired shape.

One of the most remarkable aspects of the 50,000 ton Giga Press is its ability to produce five vehicle frames simultaneously.

This capability is a game changer for Tesla, as it allows for unprecedented production speeds.

The Cyber Cab, a new vehicle model under development, is expected to benefit significantly from this technology, potentially allowing Tesla to produce a car every five seconds.

The Cyber Cab’s design focuses on reducing the number of structural components, with plans to have around 80 parts compared to approximately 200 in the Model Y.

This simplification will not only streamline production but also enhance the vehicle’s performance and range.

Tesla’s commitment to innovation extends beyond just the Giga Press.

The company has also implemented advanced cooling technologies in its casting processes, cutting cycle times and improving the overall quality of the parts produced.

These advancements have made the Model Y lighter, more precise, and more consistent, further solidifying Tesla’s position as a leader in electric vehicle manufacturing.

The introduction of the 50,000 ton Giga Press is not just about increasing production speed; it’s about redefining the entire manufacturing process.

Tesla is moving away from traditional assembly lines and adopting a model that closely resembles electronics manufacturing, characterized by speed and efficiency.

As Tesla continues to innovate, the implications for the broader automotive industry are profound.

Other automakers are beginning to take notice, with companies like General Motors and Hyundai investing in similar casting technologies.

However, none have yet matched Tesla’s ability to integrate such advanced machinery into their production lines.

The future looks bright for Tesla as it prepares to launch the Cyber Cab and other models utilizing the Giga Press technology.

If successful, these vehicles could significantly lower production costs, increase margins, and ultimately reshape the electric vehicle market.

Musk’s vision of producing affordable electric vehicles is becoming increasingly attainable with the advancements in casting technology.

The upcoming Model 2, expected to follow a similar chassis structure, could also benefit from the efficiencies gained through Giga Casting.

As Tesla continues to lead the charge in electric vehicle production, the company remains committed to pushing the envelope on what is possible in manufacturing.

With the 50,000 ton Giga Press, Tesla is not just building cars; it is building the future of automotive manufacturing.

In conclusion, the introduction of the 50,000 ton Giga Press marks a pivotal moment for Tesla and the automotive industry as a whole.

As production speeds increase and manufacturing processes become more streamlined, Tesla is poised to maintain its dominance in the electric vehicle market.

With innovative designs and advanced technologies, the company is setting new standards for efficiency and performance, paving the way for a new era in automotive production.

As we look to the future, it will be exciting to see how Tesla continues to innovate and transform the way we think about car manufacturing.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

News

New Heated Footage of Stephen Smith and Lebron James Goes Viral! – HTT

The Heated Showdown: LeBron James Confronts Stephen A. Smith Over Controversial Remarks About Bronny In a dramatic turn of events…

EVERYONE Is Suddenly Talking About Jimi Hendrix Again, You Won’t Believe Why – HTT

Jimi Hendrix’s Legacy Ignites a New Wave of Excitement: Here’s Why Everyone is Talking About Him Again In a surprising…

DeRozen and Dillion Brooks’s New Fight Footage Goes Viral! – HTT

The Explosive Rivalry: DeRozan vs. Brooks and Their Viral Fight In a dramatic turn of events during a recent NBA…

Ford & John Deere WIPES THE FLOOR With Trump On Stage & Trump LOSES IT – HTT

The Fallout of Trump’s Tariff War: How Ford and John Deere Turned the Tables In a stunning turn of events,…

Chumlee Sentenced To Life In Prison After He Did This On Pawn Stars – HTT

Chumlee’s Shocking Downfall: From Pawn Stars Favorite to Life Behind Bars Austin Russell, better known as Chumlee from the hit…

Is Elon Musk the Father of Actress Amber Heard’s Child? – HTT

The Mystery of Amber Heard’s Child: Is Elon Musk the Father? The question of whether Elon Musk is the father…

End of content

No more pages to load