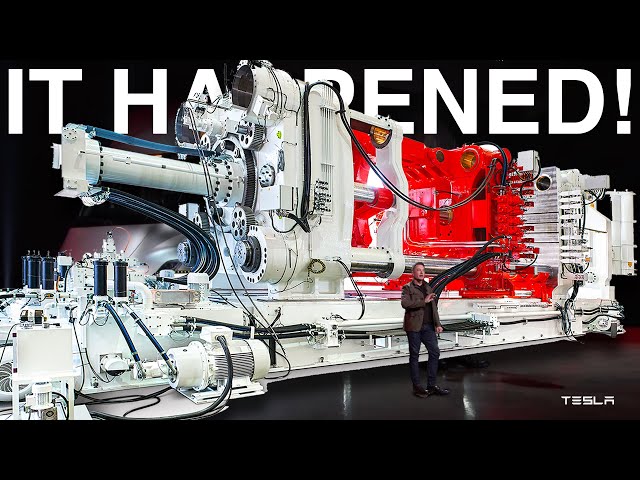

Game Over! Elon Musk Unveils the Revolutionary New Gigapress for Tesla in 2025!

Elon Musk has made a significant announcement that could reshape the future of automotive manufacturing.

The new Gigapress, set to debut in 2025, introduces a series of innovative upgrades designed to enhance Tesla’s production capabilities.

This colossal machine is not just an evolution of existing technology; it represents a fundamental shift in how electric vehicles are manufactured.

With its advanced features, the Gigapress promises to streamline production processes, reduce costs, and improve the overall quality of Tesla vehicles.

In this article, we will explore the origins of the Gigapress, the details of the 2025 upgrades, and what these advancements mean for Tesla and the global automotive industry.

Chapter 1: The Origins of the Gigapress

To understand the significance of the 2025 Gigapress upgrades, we must first look at the history of the Gigapress itself.

Introduced in 2020, the Gigapress was a groundbreaking innovation that allowed Tesla to manufacture car parts using a massive die-casting machine.

This was a first in the automotive industry, where traditionally, hundreds of smaller components were assembled to create a vehicle structure.

Manufactured by the Italian company IDRA Group, the Gigapress is capable of producing single-piece castings for vehicle components, significantly reducing the number of parts and complexity involved in assembly.

Initially, Tesla used the Gigapress to cast the rear underbody of the Model Y, which not only cut down production costs but also increased the structural integrity of the car.

As a result, Tesla achieved faster production times, reduced waste, and ultimately created a stronger vehicle.

However, Elon Musk was not satisfied with merely having a revolutionary machine; he aimed to take the Gigapress to the next level.

Chapter 2: The 2025 Gigapress Upgrades Unveiled

So, what exactly are the upgrades that Elon Musk has teased for the 2025 Gigapress?

Let’s break down the key innovations that promise to revolutionize Tesla’s manufacturing capabilities further.

New Size and Power: The first significant upgrade is the increased size and power of the Gigapress.

The new version boasts a clamping force of over 12,000 tons, up from the previous 6,000-ton models.

This increase in power allows the Gigapress to handle larger molds, enabling Tesla to cast even more substantial parts in a single shot.

Advanced Alloy Formulation: The new Gigapress is not just bigger but also smarter.

Tesla has developed a proprietary aluminum alloy specifically designed to work with the upgraded Gigapress.

This new alloy has a higher strength-to-weight ratio, meaning the parts produced will be lighter and stronger than before, with improved thermal conductivity and corrosion resistance.

Faster Cycle Times: The upgraded Gigapress features advanced cooling systems and automated mold handling technology that drastically reduce cycle times.

Tesla claims the new Gigapress can complete a single cycle in under 30 seconds, a significant improvement over previous models.

This efficiency means Tesla can produce more parts in less time, increasing overall production capacity.

Multimaterial Casting Capability: One of the most exciting upgrades is the Gigapress’s new multimaterial casting capability.

Previously limited to aluminum alloys, the new Gigapress can now handle a range of materials, including high-strength steels and composite materials.

This flexibility allows Tesla to optimize material properties for different parts of the car, enhancing safety, durability, and performance.

Integrated Quality Control: Tesla has integrated AI-driven quality control systems into the Gigapress.

These systems use advanced sensors and machine learning algorithms to detect any defects in real-time during the casting process.

If a flaw is detected, the system can automatically adjust parameters or reject the part, ensuring that only the highest quality components make it to the assembly line.

Reduced Environmental Impact: Sustainability is always a key concern for Tesla.

The 2025 Gigapress upgrades include features to reduce the machine’s environmental footprint.

The new press uses energy-efficient motors, recycles heat generated during the casting process, and minimizes waste by optimizing raw material use.

Tesla estimates that these upgrades will reduce the Gigapress’s energy consumption by up to 30%, making it one of the most eco-friendly manufacturing tools in the industry.

Modular Design for Global Flexibility: Another key innovation is the modular design of the new Gigapress.

This design makes it easier to transport and assemble the machine at different locations worldwide.

As a result, Tesla can quickly set up new production lines in gigafactories around the globe, enabling rapid scaling of operations to meet local demand.

Chapter 3: Implications for Tesla’s Manufacturing Process

Now that we know what the upgrades entail, let’s discuss their implications for Tesla’s manufacturing process.

The 2025 Gigapress upgrades have the potential to transform how Tesla builds its cars from the ground up.

By allowing Tesla to cast larger parts in a single piece, the upgraded Gigapress simplifies the production process.

Fewer parts mean fewer steps in the assembly line, reducing manufacturing complexity and speeding up production while lowering the likelihood of errors or defects.

Reducing Costs: The Gigapress upgrades promise significant cost savings.

Fewer parts mean lower material costs, and faster cycle times lead to lower labor costs.

Combined with reduced energy consumption and waste, these factors contribute to a much lower overall cost per vehicle, which Tesla could pass on to consumers, potentially lowering car prices and making them more accessible.

Increasing Production Capacity: The increased power and efficiency of the upgraded Gigapress mean that Tesla can produce more parts in less time, significantly increasing its production capacity.

This is crucial for Tesla’s plans to scale up production and meet growing demand, particularly as it prepares to launch new models and expand into new markets.

Improving Vehicle Quality and Performance: The new alloy formulations and multimaterial casting capabilities mean that Tesla can build cars that are lighter, stronger, and more durable.

This not only improves vehicle safety and performance but also enhances the overall driving experience.

Enabling New Vehicle Designs: The flexibility of the upgraded Gigapress opens up new possibilities for vehicle design.

By casting larger and more complex parts, Tesla can create more innovative and aerodynamic designs that were not previously possible.

This could lead to new models with enhanced performance, efficiency, and aesthetics, further strengthening Tesla’s position as a leader in automotive design.

Accelerating the Transition to Sustainable Energy: By making its manufacturing process more efficient, cost-effective, and environmentally friendly, Tesla is furthering its mission to accelerate the world’s transition to sustainable energy.

The upgrades to the Gigapress are critical to this strategy, allowing Tesla to produce more electric vehicles while minimizing its environmental impact.

Chapter 4: Global Expansion and Strategic Impact

The 2025 Gigapress upgrades are not just about improving manufacturing; they are also a key component of Tesla’s global expansion strategy.

As Tesla continues to build new gigafactories worldwide, the upgraded Gigapress will play a crucial role in supporting its growth plans.

Supporting New Gigafactories: Tesla has announced plans to build new gigafactories in several strategic locations, including India, Canada, and the Middle East.

These factories will need the latest technology to ramp up production quickly and efficiently.

The modular design of the new Gigapress makes it ideal for these locations, allowing Tesla to set up production lines faster and start producing cars sooner.

Enhancing Local Production Capabilities: The new Gigapress’s multimaterial casting capability is particularly valuable in regions where access to specific materials may be limited.

By allowing Tesla to use a wider range of materials, the upgraded Gigapress provides greater flexibility and resilience in its supply chain, ensuring that production can continue smoothly regardless of local conditions.

Strengthening Tesla’s Competitive Position: The Gigapress upgrades will help Tesla maintain its competitive edge in the rapidly evolving EV market.

By lowering production costs and improving vehicle quality, Tesla can continue to offer high-performance electric vehicles at competitive prices.

This will be critical as other automakers ramp up their efforts to enter the EV space.

Chapter 5: Technological Innovations Behind the Upgrades

The 2025 Gigapress upgrades are a testament to Tesla’s commitment to innovation and technological excellence.

Let’s take a closer look at some of the key technologies behind these upgrades.

Advanced Sensor Technology: One of the most critical aspects of the new Gigapress is its advanced sensor technology.

The press is equipped with a network of high-precision sensors that monitor every aspect of the casting process in real time.

These sensors provide instant feedback on temperature, pressure, mold fill, and cooling rates, allowing for precise control and optimization of the casting process.

AI-Driven Quality Control: The new Gigapress uses artificial intelligence to monitor the quality of each part it produces.

Machine learning algorithms analyze data from the sensors to detect anomalies or defects, such as air pockets or cracks.

If a defect is detected, the AI system can adjust the process parameters or reject the part, ensuring that only the highest quality components are used in Tesla’s vehicles.

Automated Mold Handling: The upgraded Gigapress features a fully automated mold handling system that reduces cycle times and increases production efficiency.

This system uses robotic arms to quickly and precisely remove finished parts from the mold and prepare the mold for the next casting cycle.

By automating this process, Tesla can minimize downtime and maximize throughput.

Energy-Efficient Motors and Cooling Systems: The new Gigapress is designed with energy efficiency in mind.

It uses state-of-the-art motors that consume less power while delivering higher performance.

Additionally, the cooling systems have been upgraded to recycle heat generated during the casting process, reducing the overall energy consumption of the machine.

Proprietary Alloy Formulations: Tesla’s new aluminum alloy formulations are a critical component of the Gigapress upgrades.

These alloys have been engineered to provide optimal strength, weight, and durability for vehicle components.

They also have excellent thermal conductivity and corrosion resistance, which help extend the lifespan of the parts and improve vehicle performance.

Multimaterial Casting Capability: The new Gigapress is capable of casting parts from multiple materials, including high-strength steels and composites.

This is made possible by an innovative heating and cooling system that allows for precise temperature control, as well as a flexible mold design that can accommodate different materials.

This capability gives Tesla greater flexibility in choosing the best materials for each component, optimizing performance and safety.

Chapter 6: The Road Ahead

So, where does Tesla go from here?

The 2025 Gigapress upgrades are just the beginning of what promises to be an exciting new chapter for Tesla and the global automotive industry.

Continued Innovation: Tesla is not one to rest on its laurels.

The company is already exploring new ways to enhance the Gigapress further, with plans to increase its size, power, and capabilities even more in the future.

Musk has hinted at the possibility of a “Mega Press” that could produce even larger parts, potentially revolutionizing the manufacturing process once again.

Expanding Production Capacity: With new gigafactories planned around the world, Tesla is set to significantly increase its production capacity in the coming years.

The upgraded Gigapress will be a central part of this expansion, enabling Tesla to produce more vehicles faster and at a lower cost.

New Vehicle Models: Tesla has several new vehicle models in the pipeline, including the Cybertruck, the Semi, and the next-generation Roadster.

The upgraded Gigapress will play a key role in producing these vehicles, allowing Tesla to bring them to market quickly and efficiently.

Focus on Sustainability: Sustainability will remain a core focus for Tesla.

The Gigapress will continue to play a key role in this effort by making the manufacturing process more efficient and reducing waste.

Tesla can lower its carbon footprint and promote sustainable practices across the industry, inspiring industry-wide change.

Chapter 7: A Game Changer for the Future

In conclusion, the 2025 Gigapress upgrades are a game-changer for Tesla and the entire automotive industry.

With its increased size and power, advanced sensor technology, AI-driven quality control, and multimaterial casting capabilities, the new Gigapress promises to revolutionize the way cars are made.

For Tesla, these upgrades mean faster production, lower costs, improved vehicle quality, and a reduced environmental impact.

For the industry, they represent a bold step forward in the evolution of manufacturing, driving innovation and setting new standards for efficiency and sustainability.

As Elon Musk and Tesla continue to push the envelope, the world watches with anticipation.

The Gigapress is not just a machine; it’s a symbol of Tesla’s relentless pursuit of excellence and its commitment to creating a better, more sustainable future for all.

The 2025 upgrades are just the beginning, and we can’t wait to see what comes next.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

News

Before His Death, Apollo 11’s ‘Third Astronaut’ Michael Collins FINALLY Admitted It – HTT

Michael Collins’ Final Admission: The Untold Truth Behind Apollo 11 Before his death, Michael Collins, the “third astronaut” of Apollo…

China’s New Moon Discovery Leaves the U.S. Stunned and Rewrites History – HTT

China’s Groundbreaking Moon Discovery Stuns the U.S. and Rewrites Lunar History In a stunning announcement that has left the world,…

Melania ERUPTS After Lincoln Project DROPS BOMBSHELL on Trump! – HTT

Melania’s Explosive Reaction: The Lincoln Project’s Devastating Blow to Trump! The Lincoln Project has struck again, and this time they’ve…

Alec Baldwin DESTROYS Trump—His Furious Meltdown Goes Viral! – HTT

Alec Baldwin’s Hilarious Take Down of Trump: The Meltdown That Broke the Internet! Alec Baldwin has done it again, and…

Elon Musk: “i am releasing Tesla’s NEW $12,000 House for 2025” – HTT

Elon Musk Unveils Tesla’s Revolutionary $12,000 House for 2025: A Game Changer in Sustainable Living! In a groundbreaking announcement that…

IT HAPPENED! Elon Musk FINALLY Reveals New Warp Drive Starship! – HTT

Elon Musk Unveils Groundbreaking Warp Drive Starship: The Future of Space Travel is Here! In a stunning revelation that has…

End of content

No more pages to load