The Tesla Time Warp: How 14 Seconds Changed Everything

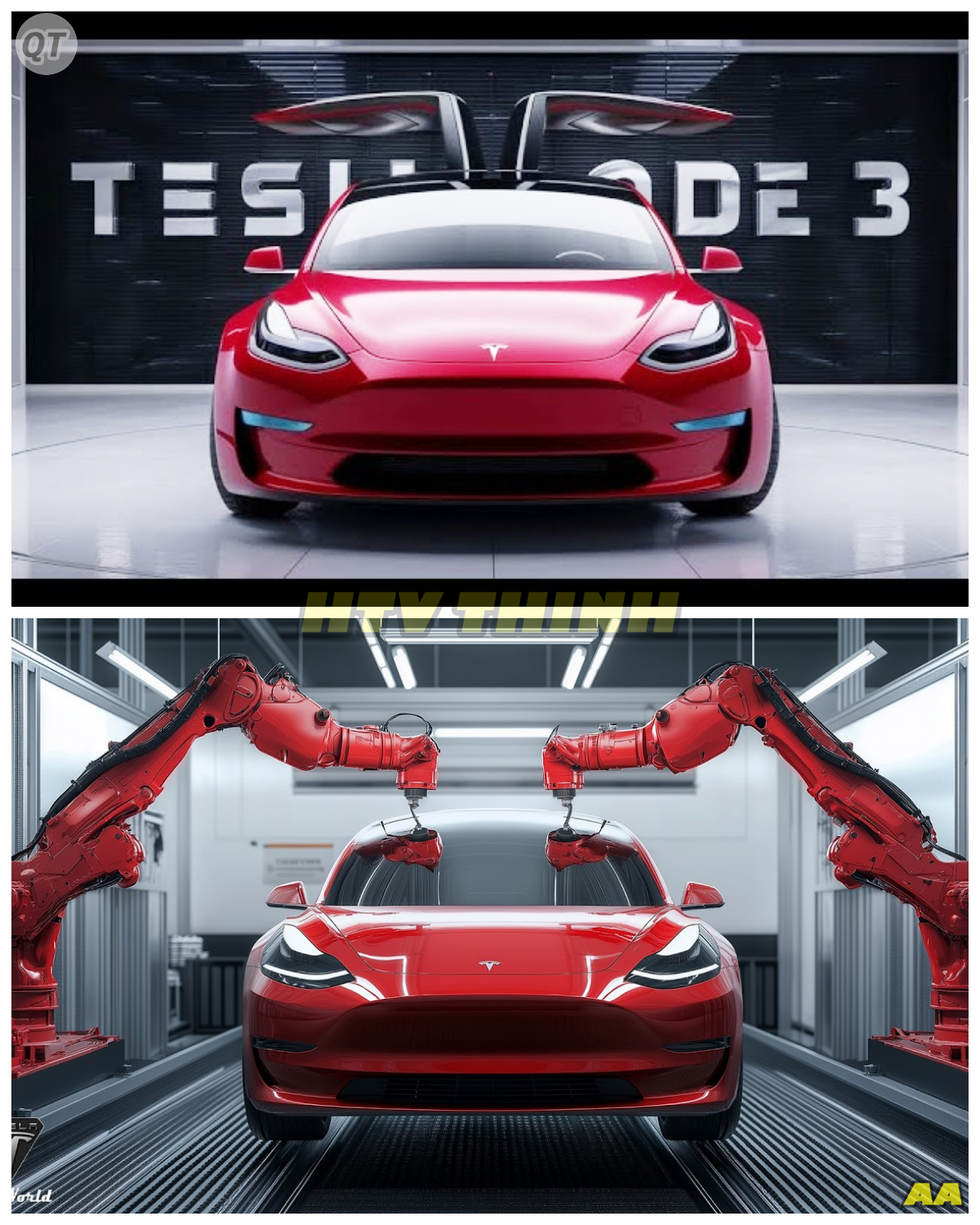

In the bustling heart of Gigafactory Texas, a new era was dawning.

Elon Musk, the visionary CEO of Tesla, stood before a crowd of eager reporters and industry insiders.

His announcement was nothing short of revolutionary.

“We are on the brink of achieving something truly extraordinary,” he declared, his eyes gleaming with excitement.

“A production cycle of just 14 seconds per electric vehicle.”

The room buzzed with disbelief and curiosity.

How could such a feat be possible?

Musk explained that this was not merely a fantasy but a reality forged by Tesla’s relentless innovation and commitment to automation.

“Our Gigafactories operate at an astonishing 95% level of automation,” he continued.

“With robotic arms and vertically stacked production lines, we’re redefining manufacturing efficiency.”

Images of sleek, futuristic factory floors flashed on the screen behind him, capturing the audience’s imagination.

“Our welding shop is nearly 100% automated,” he added, underscoring the technological marvels at play.

The implications of this were profound.

Tesla had slashed manufacturing defects to less than 1%, a dramatic improvement from the 5% defect rate of just a few years ago.

“Quality control that once took 24 hours now takes just 1 hour per batch,” Musk noted, drawing applause from the audience.

“Imagine the possibilities!” he exclaimed, his voice filled with enthusiasm.

“A 14-second production cycle could skyrocket our vehicle output to unprecedented levels.”

He shared an example of the current production capacity at Gigafactory Texas.

“Right now, we produce around 6,000 Model Ys per week with a production time of 30 seconds per vehicle.”

He paused, letting the numbers sink in.

“That equates to 120 EVs per hour, totaling 20,160 vehicles weekly.”

But with a 14-second cycle, the potential was even greater.

The audience was captivated, hanging on his every word.

“At 14 seconds per vehicle,” Musk explained, “we could potentially produce over 25,000 vehicles per week!”

This revelation sent ripples through the automotive industry.

Competitors who once dismissed Tesla as a niche player now realized they faced a formidable challenge.

“We’re not just building cars,” Musk declared, his voice resonating with conviction.

“We’re building the future.”

As the presentation concluded, Musk invited a team of engineers to the stage.

“Meet the brilliant minds behind this innovation,” he said proudly.

Among them was Sarah, a lead engineer who had been with Tesla since its early days.

“When I joined Tesla,” she recalled, “we were just a small startup with a big dream. Now, we’re on the verge of transforming the automotive landscape.”

Sarah elaborated on how they integrated AI and 3D printing into the production process.

“AI allows us to optimize every step of manufacturing,” she said.

“And with 3D printing, we can create parts faster and more efficiently than ever before.”

The audience listened intently, absorbing the groundbreaking advancements.

“But that’s not all,” she continued.

“Our Giga Press application has revolutionized vehicle assembly. We can now create large components in a single piece, reducing assembly time and enhancing structural integrity.”

As the day unfolded, Musk and his team shared more insights into Tesla’s future.

They discussed plans to expand Gigafactories globally, replicating their success in Texas.

“We’re committed to sustainability,” Musk emphasized.

“Every vehicle we produce is a step towards a greener planet.”

The excitement in the room was palpable.

Investors were eager to learn more, and journalists scrambled to capture every detail.

“What does this mean for consumers?” one reporter asked.

Musk smiled, “It means more affordable electric vehicles, faster delivery times, and an unmatched commitment to quality.”

As the conference wrapped up, Musk took a moment to reflect.

“When I look at what we’ve accomplished,” he said, “I’m filled with gratitude for the incredible team that made this possible. But this is just the beginning.”

The future of Tesla was bright, and the automotive world was watching closely.

In the following months, the company began implementing the new production cycle in phases.

Sarah and her team worked tirelessly, fine-tuning processes and ensuring smooth operations.

“It’s challenging,” she admitted, “but the excitement of being part of something groundbreaking keeps us motivated.”

As the first vehicles rolled off the assembly line at the new speed, the results were astonishing.

Production times were slashed, and quality remained impeccable.

Musk’s vision was becoming a reality, and the impact on the market was immediate.

Competitors were forced to innovate or risk being left behind.

“We have to adapt,” said Rachel, a rival CEO. “Tesla is setting the pace, and we need to keep up.”

As the months turned into years, Tesla’s influence on the automotive industry was undeniable.

The 14-second production cycle became a standard that others aspired to achieve.

Musk was hailed as a visionary, and Sarah became a celebrated figure in engineering circles.

“This isn’t just about cars,” she said in an interview. “It’s about changing the way we think about manufacturing and sustainability.”

The world watched as Tesla continued to break barriers, proving that with innovation and determination, anything was possible.

In the end, Tesla’s story was not just about electric vehicles; it was about a movement towards a better, more sustainable future for all.

Elon Musk had indeed unveiled how they could do it in only 14 seconds, and the world would never be the same again.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

News

Dolly Parton Sentenced For Her Husband’s Death, Goodbye Forever

The Shocking Truth Behind Dolly Parton’s Sentence In a twist that no one saw coming, the beloved queen of country music, Dolly…

Oldest Hollywood Stars You Didn’t Know Are Still Alive Today

Timeless Legends: The Oldest Hollywood Stars Still Shining In a world that often forgets its icons, there are a few…

Serena Williams’s Husband Is Saying Goodbye After Her Tragic Diagnosis

A Love That Endures: The Heartbreaking Journey of Serena Williams In the world of sports, few names shine as brightly…

Dolly Parton Leaves Behind a Fortune That Makes His Family Cry

The Emotional Legacy of Dolly Parton: A Fortune That Moves Hearts In the heart of the Smoky Mountains, Dolly Parton…

Drew Barrymore CRIES And Resigns on Live TV

The Heart-Wrenching Moment: Drew Barrymore’s Live TV Resignation On a seemingly ordinary day, Drew Barrymore, the beloved Hollywood actress and…

Tesla Model Q 2025 Is Here! Elon Musk Will Releases NEW Car For Shocking Price, More Updates!

The Future of Driving: The Tesla Model Q and Its Impact on the Automotive Industry In a world where electric…

End of content

No more pages to load