What SpaceX just did with Starship V3 WELDING Shocked NASA scientists.

In yet another bold leap forward for private spaceflight, SpaceX has left the aerospace community—especially scientists at NASA—stunned with its latest breakthrough: an advanced welding technique being implemented on the Starship Version 3 prototype.

The innovation not only pushes the boundaries of engineering but could also redefine how spacecraft are built, both on Earth and potentially in orbit.

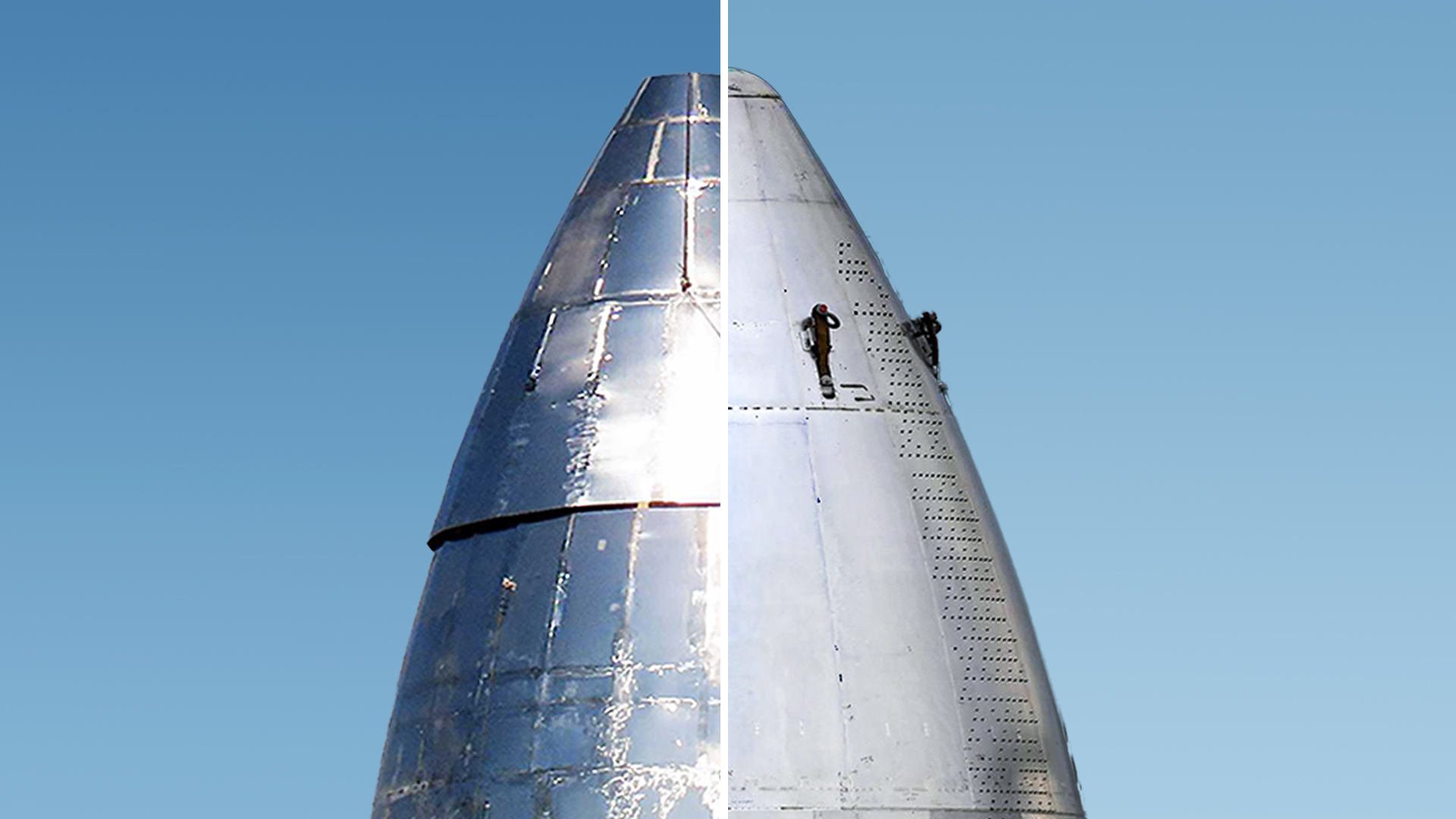

According to multiple reports and leaked images from SpaceX’s Starbase facility in Boca Chica, Texas, the company has introduced a completely reengineered weld system on the V3 variant of Starship.

The quality, consistency, and scale of the welds have drawn comparisons to aerospace-grade perfection, something that is notoriously difficult to achieve when working with stainless steel, the primary material used in the Starship’s body.

Experts are now calling this a “quiet revolution” in spacecraft manufacturing.

What stunned NASA scientists the most was the precision of these new welds, which are so fine and seamless that they’re barely visible to the naked eye.

In earlier versions of Starship, SpaceX used conventional robotic welding systems, which left visible seams and occasional cosmetic imperfections—nothing mission-critical, but far from aesthetically clean.

The new approach with V3 suggests a massive upgrade in both equipment and process, possibly involving a proprietary blend of laser and friction-stir welding, enhanced by AI-driven real-time quality control.

Sources familiar with the operation claim that SpaceX’s engineering team has been working for months to refine this process.

The goal was simple: increase structural integrity while also reducing the need for post-weld inspections and repairs, which are time-consuming and expensive.

Early tests of the V3 hull using cryogenic pressure simulations show a dramatic improvement in performance, withstanding higher loads and less flexing under stress.

NASA engineers, who have collaborated with SpaceX on missions like Crew Dragon and Artemis support, were invited for a private viewing of the V3 structure last week.

According to insiders, some of them were “completely floored” by what they saw.

One unnamed source reportedly stated, “We’ve never seen welds this clean on stainless steel at this scale.

If this holds up under orbital conditions, it’s a game-changer for deep space missions.

The impact of this innovation stretches beyond just aesthetics or structural performance.

By improving the welding process, SpaceX is also making strides toward achieving full reusability, a core element of its long-term strategy.

Tighter, stronger welds mean less wear and tear with each launch and return, which directly translates into cost savings and faster turnaround times.

This also aligns with CEO Elon Musk’s vision of launching, landing, and relaunching Starship vehicles like commercial airliners.

Observers at Starbase noticed another interesting detail: the V3 variant appears to have fewer weld joints altogether.

That could mean SpaceX has found a way to fabricate larger single pieces of stainless steel, or it has upgraded its tank and segment design to require fewer connections.

Either way, it results in a lighter, stronger, and more efficient structure—essential for reaching Mars or conducting point-to-point missions on Earth.

Elon Musk himself hinted at the breakthrough on X (formerly Twitter), stating cryptically: “V3 welds are next-level.

You have to see them to believe them.

” As always, Musk didn’t go into specifics, sparking a wave of speculation and curiosity among space enthusiasts and engineers alike.

Within hours, satellite imagery and drone footage of the Starbase site were being analyzed frame by frame by fans hoping to get a closer look at the mysterious new methods.

NASA’s involvement in observing this development is particularly notable.

Though the agency has long relied on traditional aerospace contractors, its growing partnership with SpaceX has opened new doors in terms of rapid innovation.

With the Artemis missions aiming to return humans to the Moon and eventually Mars, technologies like those seen in Starship V3 could prove critical to mission success.

If these welding techniques prove viable in space conditions, NASA might even adopt or adapt them for its own vehicles, or include them in its specifications for future lunar landers and habitats.

The public response has been just as excited.

Across forums, YouTube channels, and social media, aerospace fans are praising the leap forward.

Many see it as further evidence that SpaceX isn’t just iterating—it’s innovating at a pace that leaves even governmental organizations scrambling to keep up.

The Starship program, still in its developmental phase, has seen rapid progression from crude prototypes to towering metallic giants capable of reaching the edge of space.

With V3, the project is entering a new chapter of precision engineering.

Of course, questions remain.

The new welds haven’t yet been tested under the rigors of a full orbital launch.

Critics caution that real validation will come only after a successful flight and recovery.

Additionally, it’s unclear whether this welding technique can be replicated at scale in the kind of high-volume manufacturing environment SpaceX envisions for its Mars colonization plans.

But if history is any indicator, SpaceX is more than capable of refining and industrializing its processes once a breakthrough has been achieved.

There’s also curiosity about what this means for competitors like Blue Origin, ULA, and even international agencies like ESA and Roscosmos.

With SpaceX constantly setting new benchmarks in cost, design, and speed, the pressure is on for other players in the space industry to evolve or risk becoming obsolete.

For now, all eyes remain on the V3 Starship, which stands as a gleaming testament to SpaceX’s commitment to pushing limits.

Whether or not NASA eventually incorporates this welding breakthrough into its own projects, the excitement is undeniable.

And in a world where space travel is becoming more than just a dream, these small technical victories are laying the foundation for the next giant leap.

News

Pop the Champagne! Jennifer Garner and John Miller’s Public Display of Affection Sparks Fan Frenzy

Jennifer Garner and John Miller Spotted in a Rare Public Display of Affection as Paparazzi Capture a Romantic Kiss…

Angelina Jolie Silences the Room With Just One Sentence—And Everyone Thinks It Was a Brutal Dig at Blake Lively

Angelina Jolie DROPS BOMBSHELLS On Blake Lively With Just ONE SENTENCE!? Angelina Jolie has once again stirred the Hollywood waters—this…

Greg Gutfeld Breaks the Silence About Why He and His Wife Never Had Children—and It’s Not What You Think

The SHOCKING Reason Greg Gutfeld & His Wife Don’t Have Kids Greg Gutfeld, the sharp-tongued, quick-witted host of “Gutfeld!” and…

Mel Gibson Finally Reveals the Deep Truth Behind Val Kilmer’s Escape from Hollywood’s Darkest Temptations

Mel Gibson SPEAKS On How Val Kilmer ESCAPED The Dark Side Of Hollywood In a rare and deeply personal moment,…

Rick Harrison’s Former Assistant Drops Bombshell Testimony in Court, Revealing Shocking Behind-the-Scenes Secrets

BREAKING: Rick Harrison’s Former Assistant TESTIFIES In Court, The Truth Is Revealed In a courtroom drama that has captured the…

Katy Perry’s Rocket Launch PR Disaster: Backlash, Regret, and Wendy’s Shade Leave Her Public Image in Ruins

Katy Perry CRUMBLES from BACKLASH to Space Rocket PR Stunt! REGRET as Even Wendy’s REFUSES Apology! Katy Perry, the globally…

End of content

No more pages to load